Creating personalized hats for your own brand isn’t difficult — the key lies in finding the right manufacturing partner. Trâm Anh Caps is honored to support you in solving this challenge quickly and effectively.

Whether you’re a company looking to produce custom hats for uniforms or corporate gifts, or an individual planning to start a hat business without investing in a factory, machinery, or labor — the simplest and most efficient solution is to find a professional hat manufacturing facility near you.

Benefits of Partnering with a Hat Manufacturing Workshop

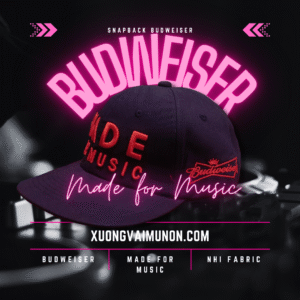

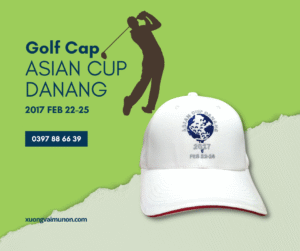

Get full support for personalized hat design: If you don’t have a specific design idea, the hat manufacturer will help create one based on your needs, expectations, and purpose. If you already have a design, they can produce hats that closely match your sample, depending on available materials, costs, and other factors. The workshop will advise you on how to create hats that best reflect your brand identity.

No need to invest in production facilities: You don’t have to worry about factories, machines, technology, or labor — the hat manufacturer takes care of it all.

Optimize your budget by skipping intermediaries: Working directly with a custom hat factory helps you avoid third-party fees. The larger the order, the greater the cost advantages and discounts you can enjoy.

If you’re based in Ho Chi Minh City, there are many reputable hat manufacturers to choose from, such as Trâm Anh Caps, Đồng Tâm Caps, Mu Non Sai Gon, or Dong Phuc GLU.

Personalized Hat Production at Trâm Anh Caps

Among Vietnam’s many hat manufacturers, Trâm Anh Caps stands out as a leading OEM/ODM hat producer. Not sure what OEM/ODM means? You can check out our previous article here.

In simple terms, Trâm Anh Caps can either produce hats based on your existing designs or handle the entire process — from design and product development to manufacturing. In both cases, you retain full rights to distribute and market your personalized hat line under your own brand name.

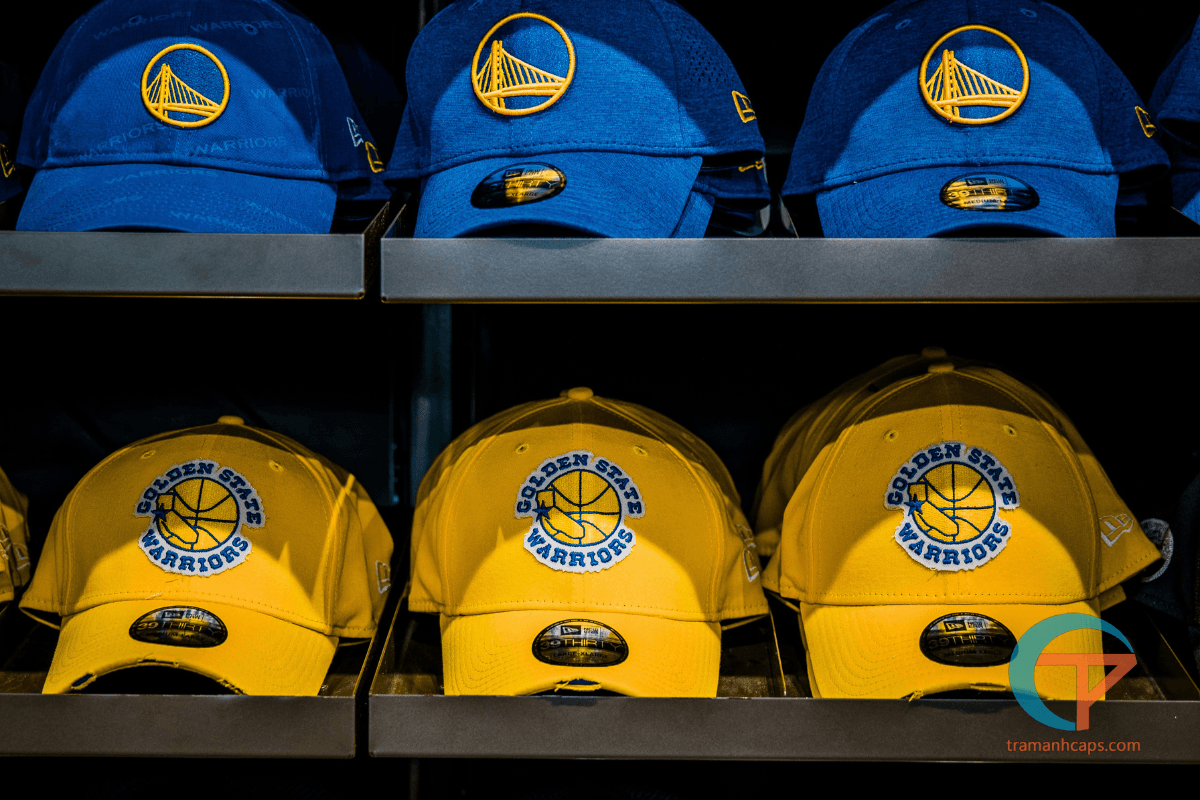

Logos, company names, and slogans are what make your hat orders truly unique. After discussing your requirements, Trâm Anh Caps will create digital mockups for your approval before proceeding to physical sampling.

Trâm Anh Caps’ Large-Scale Personalized Hat Production Process:

- Material sourcing: Trâm Anh Caps helps you find materials that exactly match or closely resemble your samples (in case the original material is unavailable in Vietnam). We focus on aesthetics, quality consistency, and cost-efficiency to ensure durable and refined products.

- Fabric cutting: Once materials are selected, the fabric is cut in bulk according to the approved pattern.

- Logo embroidery or printing: Your logo, image, company name, or slogan will be printed or embroidered using advanced machinery and textile-specific technology for precise, high-quality results.

- Assembly and stitching: Each component is then assembled through various production stages, including sewing panels, brims, straps, and finishing the hat structure.

- Quality control: Every step of production undergoes strict quality inspection to ensure over 90% product completion with no major defects before moving forward.

- Steaming and shaping: This step refines the hat’s form, giving it a neat, high-end appearance.

- Final inspection and packaging: Products are checked again to ensure no deformation or seam cracking occurred during heat shaping. Finally, Trâm Anh Caps packages and delivers your hats on schedule.

Trâm Anh Caps is proud to be trusted by renowned brands such as Coca-Cola, Boss, HSBC, Hoa Sen Group, and VietinBank.