When ordering caps and hats in large quantities for businesses, schools, or events, many organizations encounter unexpected additional costs due to incomplete preparation and unclear requirements from the beginning.

In this article, Trâm Anh Caps provides a detailed checklist of essential items that must be prepared when ordering caps and hats in bulk, helping you control your budget, optimize unit pricing, and avoid unnecessary risks during the production process.

1. Clearly Define the Intended Use of the Caps and Hats

This is a crucial step that is often overlooked. Each intended use requires a different cap style, fabric, and production method.

- Staff uniforms: prioritize durability, proper structure, and clear logos

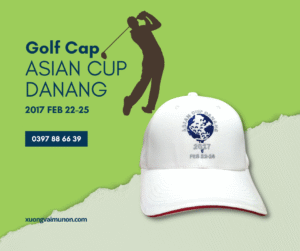

- Events & activations: prioritize eye-catching visuals and cost efficiency

- Customer gifts: balance aesthetics with budget

Defining the purpose from the beginning allows the factory to recommend the most suitable solution and helps avoid design changes or revisions later.

2. Finalize the Cap Style and Type Early

Each cap type has a different structure, material usage, and production workflow. Common cap styles for bulk orders include:

- 5-panel / 6-panel baseball caps

- Bucket hats

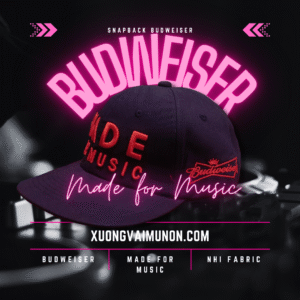

- Snapback caps

- Mesh caps (trucker caps)

Changing the cap style midway through production can result in additional costs for molds, patterns, or extended production time.

3. Confirm Fabric Materials and Accessories

Fabric choice significantly affects both the unit price and durability of the caps and hats. Common materials include:

- Cotton twill / polyester twill

- Canvas fabric

- Mesh fabric, knit fabric, nylon fabric

In addition, accessories such as plastic or metal closures, ventilation eyelets, inner linings, and labels should be clearly confirmed to avoid extra charges.

4. Prepare Logo Files to Technical Standards

The logo plays a key role in determining the printing or embroidery method and production costs.

- Provide vector files (AI, PDF, SVG)

- Specify the desired logo size

- Confirm the logo placement on the cap

Logos that do not meet technical requirements may require additional file processing, leading to extra time and costs.

5. Confirm Order Quantity and Delivery Timeline

For large-quantity cap and hat orders, quantity and schedule directly impact the production plan.

- Finalize the quantity as early as possible

- Clearly communicate the required delivery deadline

- Allow time for sample testing and production approval

Is Bulk Cap and Hat Pricing Fixed?

There is no fixed price for bulk cap and hat manufacturing, as costs depend on:

- Cap style and structure

- Fabric materials used

- Logo printing or embroidery method

- Order quantity

- Accessories and custom requirements

To avoid unexpected costs, businesses should work directly with the manufacturing factory from the initial consultation stage.

Bulk Cap and Hat Manufacturing at Trâm Anh Caps

As a direct cap and hat manufacturing factory, Trâm Anh Caps helps clients:

- Receive detailed consultation on every item before production

- Proactively control costs and timelines

- Minimize unnecessary additional expenses

- Ensure consistent quality and brand identity

Contact Trâm Anh Caps for tailored consultation and a detailed quotation based on your actual requirements.