As a professional hat manufacturing workshop with over 10 years of experience, Trâm Anh Caps can produce a wide range of hat styles. The company has the capability to meet customers’ specific requirements with precision and consistency.

Types of Hats Produced by Trâm Anh Caps

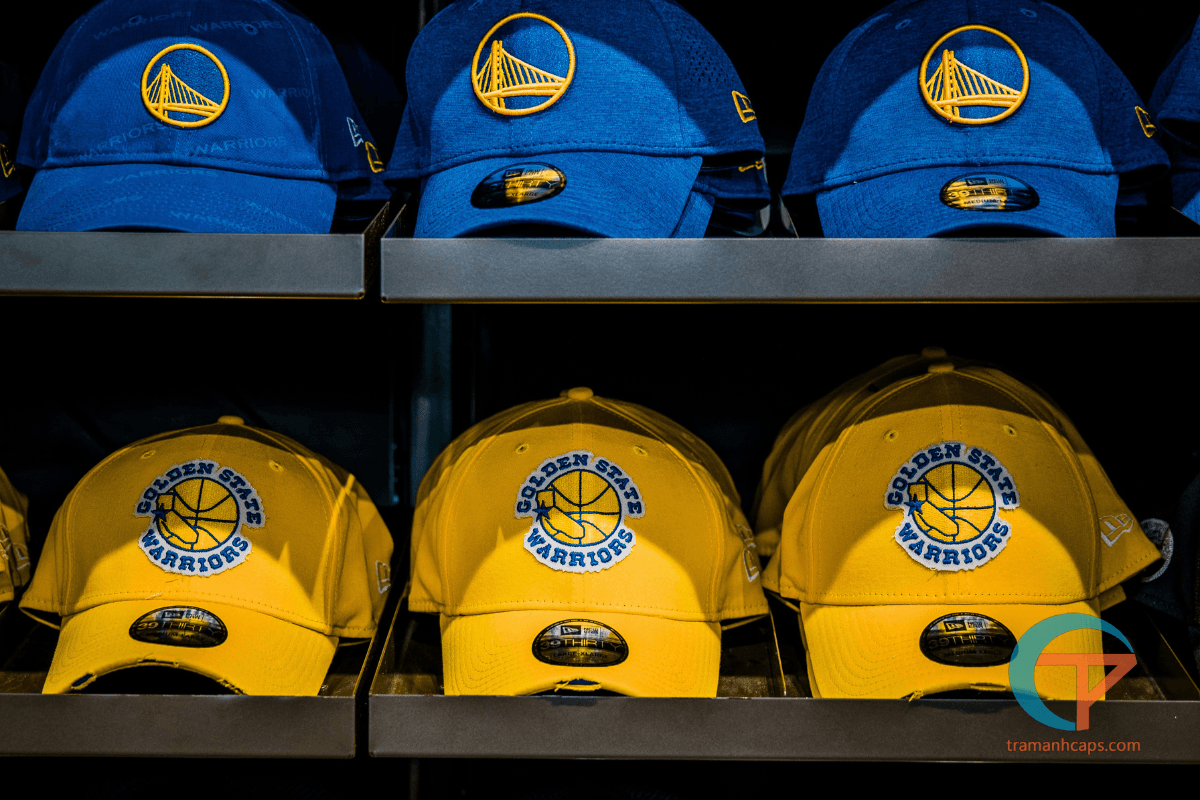

Baseball Caps

Baseball caps (also known as snapback caps) are among the most popular types of hats — not only in Vietnam but also worldwide. They feature a visor in the front, usually 15–20 cm long, to block sunlight, wind, and improve visibility.

Baseball caps are one of the top-selling products made by Trâm Anh Caps. Businesses and organizations often order these caps for advertising, corporate gifts, or staff uniforms. Their unisex design and versatile style make them timeless and always in demand.

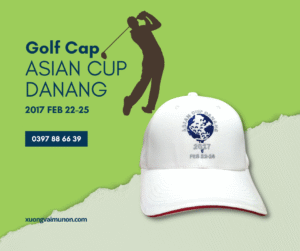

Premium Golf Caps

Golf caps are designed for high-end users and elite golfers, requiring excellent quality and durability for outdoor use. The two main types of golf hats are baseball-style and wide-brim caps. Both are crafted from breathable, lightweight fabrics with bright tones and minimal patterns.

Golf hats may include adjustable straps or ventilation eyelets made from fabric, plastic, or metal for added comfort and customization.

Trâm Anh Caps has collaborated with prestigious brands such as FLC, Long Thành Golf Course, Tân Sơn Nhất Golf Course, and Twin Doves. Their premium golf hats have proudly served government officials, influencers, and successful entrepreneurs.

Advertising Hats

Advertising hats are commonly used as promotional gifts or event merchandise. They are embroidered or printed with the brand’s logo, visuals, and signature colors to increase brand recall among both customers and the general public.

Trâm Anh Caps has produced promotional hats for leading corporations such as Shell Lubricants, Hoa Sen Steel, and Vietcombank.

Uniform Hats

Similar to advertising hats, uniform hats feature the brand’s logo, name, or visual identity. The key difference is their purpose — these hats are part of employee uniforms, helping businesses build a cohesive, professional, and unified image. Typically, Trâm Anh Caps produces compact, convenient baseball-style uniform caps suitable for both men and women.

Travel Hats

This hat category is highly popular among travel companies that organize tours. Travel hats are often given to customers as uniforms during trips — not only as a gesture of care but also as an effective way to promote the brand. Groups of travelers wearing matching logo-printed hats create strong visual impressions and brand recognition.

Travel hats come in various styles such as baseball caps, bucket hats, wide-brim hats, or half-brim hats. Most travel companies prefer caps or bucket hats for convenience and comfort.

Fashion Hats

Fashion hats are stylishly designed accessories that reflect personal taste and individuality. Businesses or retailers in the fashion industry often manufacture or outsource these hats in bulk to reduce unit cost while maintaining high design appeal and quality.

Bucket & Wide-Brim Hats

These are among the most popular hat styles frequently produced by Trâm Anh Caps. Bucket and wide-brim hats offer excellent sun protection, featuring large brims and adjustable chin straps to prevent them from blowing away. Users can easily fold or adjust the brim for comfort and style.

The design is modern and fashionable. Depending on the model, these hats can be suitable for women only or for both genders.

Trâm Anh Caps’ Hat Production Process

Over the past 10 years, Trâm Anh Caps has optimized its hat manufacturing process into 7 key steps:

Step 1: Source suitable materials that closely match the customer’s sample. Trâm Anh Caps carefully selects fabrics that meet aesthetic, quality, and cost standards to ensure durable, consistent, and beautiful products.

Step 2: Cut fabrics in bulk based on approved design templates. Customers review both digital mockups and physical samples before production.

Step 3: Embroider or print logos, images, company names, or slogans according to the design. This step is executed using advanced, automated machines for precision and consistency.

Step 4: Assemble and stitch all hat components through multiple production lines specific to each hat type, forming the nearly finished product.

Step 5: Inspect all products to ensure over 90% completion with no major defects.

Step 6: Steam, press, and shape the products for a clean, professional finish.

Step 7: Conduct final quality checks to ensure pressing and shaping did not cause shrinkage or thread cracking. Finally, Trâm Anh Caps packages and ships the products to customers.

Contact Trâm Anh Caps today to create and customize any hat design you envision!